POSITION: HOME > SOLUTION

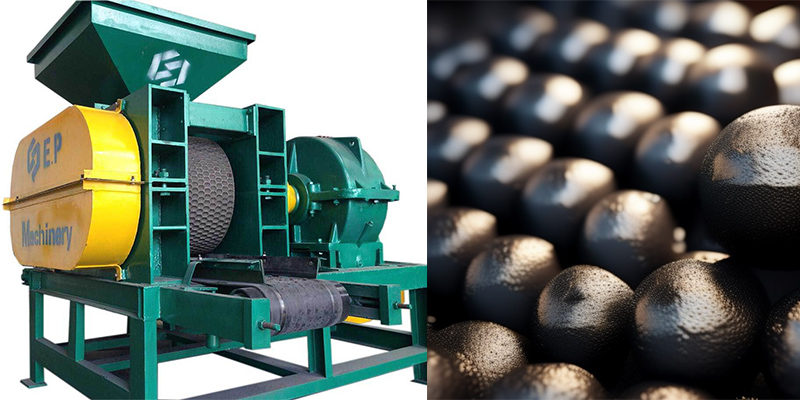

briquetting (ball pressing) machine is a heavy-duty machine widely used in metal recycling, plastic processing and agricultural feed manufacturing. Its working principle is to compress loose materials into blocks by high pressure for easy transportation and storage. The use of this equipment not only promotes the reuse of materials and reduces production costs, but also has a positive impact on environmental protection.

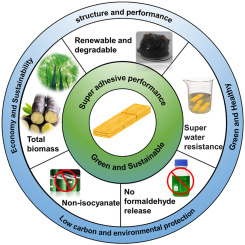

Adhesives, with their unique properties, play a key role in various industrial and daily life applications. There are many types of them, and they can be mainly divided into three types: organic, inorganic and composite.

Biomass charcoal molding plant, as an emerging force in green energy, is gradually entering our field of vision. This important achievement in the field of environmental protection technology not only plays an important role in reducing deforestation and reliance on traditional fossil fuels, but also wins the recognition and support of the general public with its unique production methods and environmental protection concepts.

Coal briquetting machine is a good helper for small and medium-sized investors to get rich. It is the best-selling briquetting machine model in both domestic and overseas markets. Especially for users who are new to making briquettes, it is a mature tool.

The briquette briquetting machine uses a high-performance electric motor as the power, which is transmitted to the drive shaft through the pulley and coupling, ensuring the stability and reliability of the power. At the same time, the driven shaft and the driving shaft rotate in opposite directions through gears, maintaining synchronization. This design ensures smooth movement of the rollers, resulting in smoother briquette production.