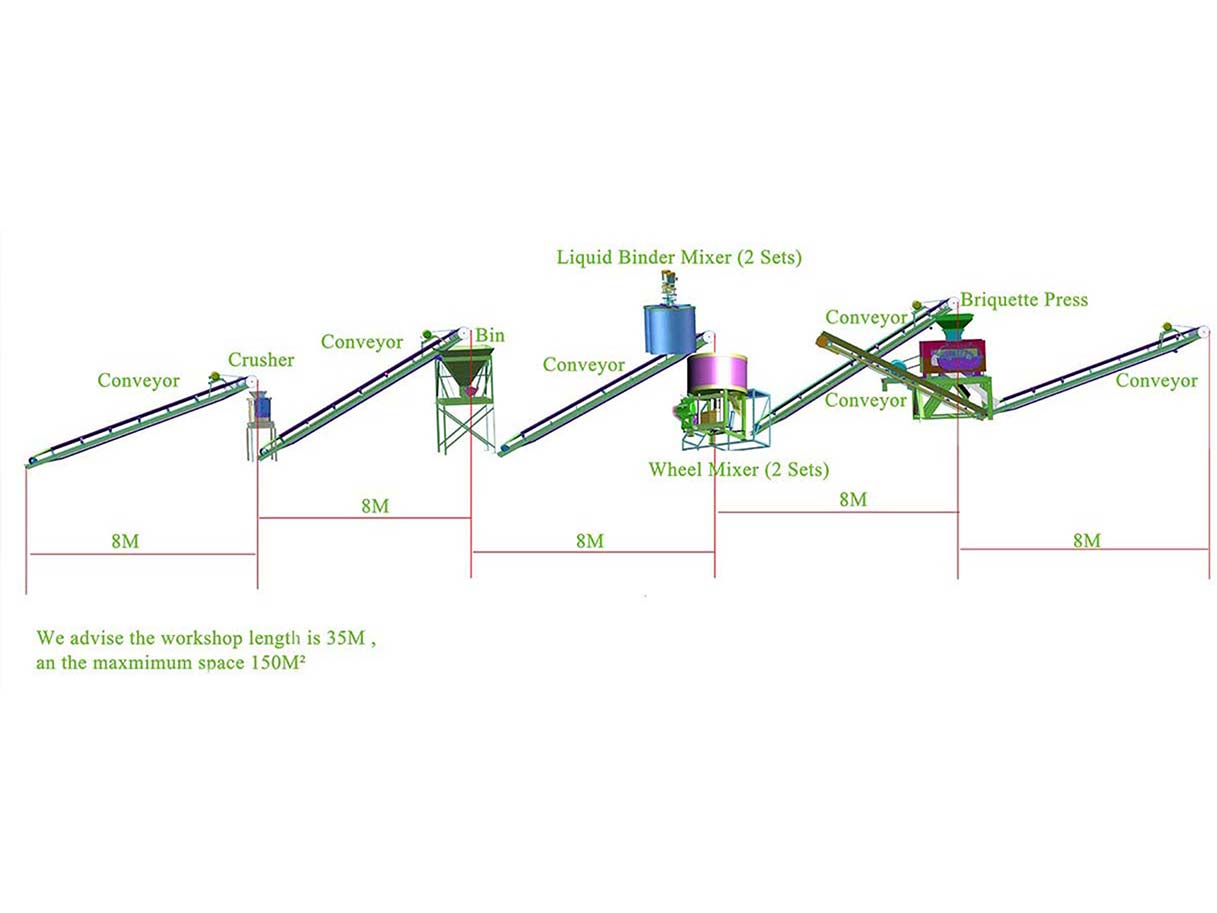

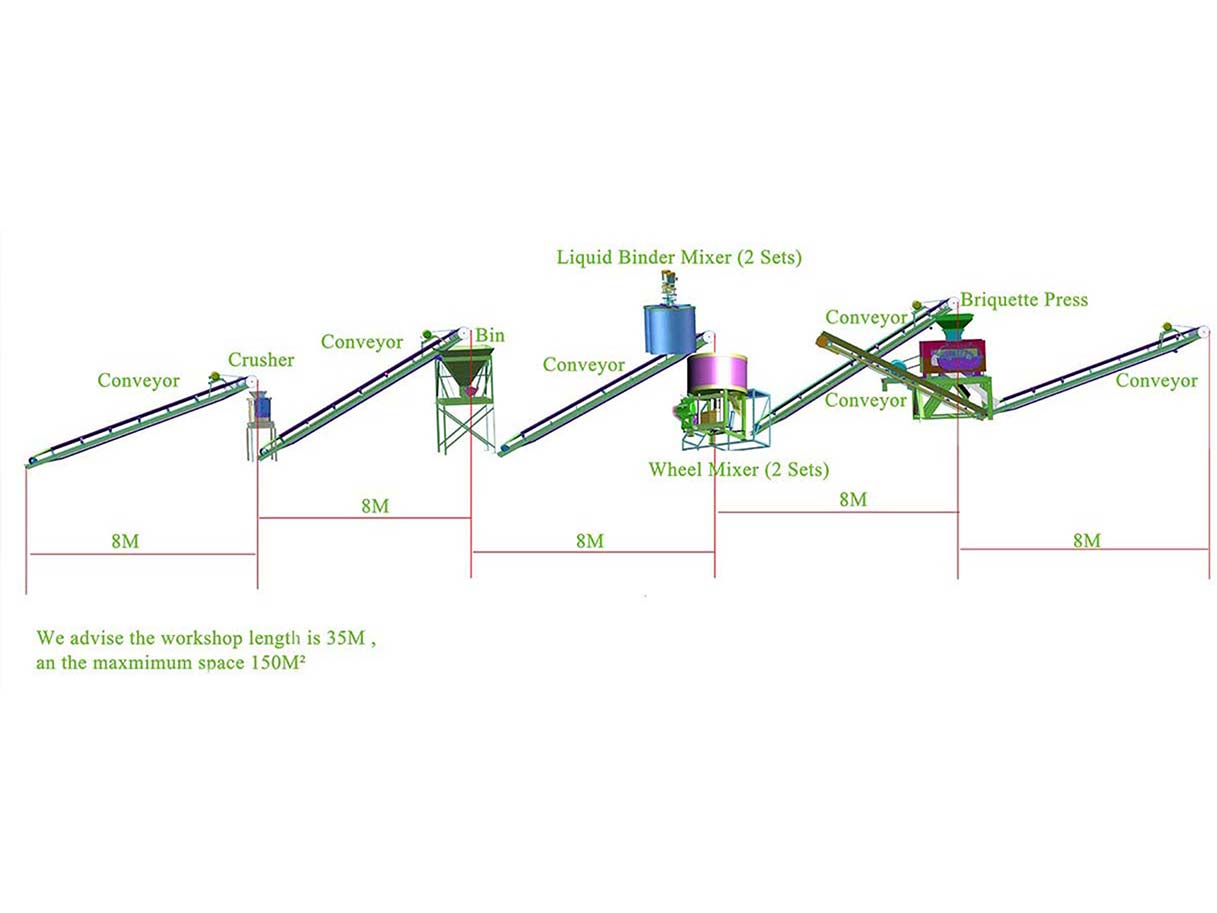

Description of the coal briquette production line process

A. Raw materials crushing system

1. Raw materials silo ---This silo is for storing the coal materials use.

2. Belt conveyor1 ---This belt conveyor is used to transport the raw materials from the silo under the ground into the next step.

3. Drum Crusher—For crushing coal, there are many different kinds of crusher. The drum crusher is good for well sealing. It can help you to reduce the dust comparing with other kinds of crusher. After crushing, the size of raw materials will be kept below 3mm.

4. Belt conveyor2 ---This belt conveyor is used to transport the crushed materials from the drum crusher into the next hopper.

B. Raw materials drying system

1.Hopper---This hopper is for storing materials for buffering function before drying, it has been installed one belt conveyor to discharge the materials in required speed. This motor of the hopper will be installed one inverter to adjust the speed.

2. Belt conveyor3 ---This belt conveyor is used to transport the coal materials from the hopper into the drying machine.

3. Rotary dryer

----The rotary dryer is used for reducing the moisture content of the raw materials. You can adjust the rotation speed to dry raw materials with different moisture. There is dust collecting system at the end of the dryer to keep the environment clean.

Note:The gas burner, diesel burner and coal burner can be optional. We also can purchase for users.

C. Raw materials and binder dosing system

1. Belt conveyor 4 ----The belt conveyor is used for transporting the dried coal materials into the twin distribution hopper.

2. Screw conveyor---It is to feed the binder into the twin distributor hopper before briquetting process. It can save a lot of labor.

3. Twin distribution hopper---This hopper is for buffering function. There are two hoppers here, one big hopper is for coal materials and the other small one is for dry binder. This distributor hopper can help you to control the percentage of raw materials and dry binder.

D. Raw materials and binder mixing system

1. Belt conveyor 5---This belt conveyor is used to transport the mixed raw materials from the twin distribution hopper to the twin-shaft mixers.

2. Twin shaft mixer – The twin shaft mixer is a very important machine for making the coal materials and binder mixed well. After mixing by this mixer, the well mixed materials will be sent to next step.

E. Briquette forming system

1.Belt conveyor 6---This belt conveyor is used to transport the well mixed raw materials to the pre-pressing process.

2.Deironing separator--The function of it is to remove any iron materials inside of coal materials to ensure the pure coal materials before briquetting.

3. Briquette Machine – A forming machine to make the compressed coal dust, Coke, charcoal, or Iron Powder and metal powder into solid briquettes, the finished briquettes can be used for fuel, kindling and other Industry use. The Raw Materials will by formed by the two squeezing Roller of the machine and the final products have high density and easy to burn, long lasting burning as well. It is hydraulic type briquette machine here and the material of its rollers is special alloy steel with longer lifespan.

4. Belt conveyor 8--The conveyor is for conveying the unformed briquettes back to the conveyor for briquetting one more time.

5.Belt Conveyor 9 – This belt conveyor is used for transporting the final briquettes to the next step--briquette drying machine.

F. Briquette drying system

1.Briquette drying machine--- It is to reduce the finished coal briquettes moisture. The breakage is very low compared with other type drying machines. The drying efficiency is the best.

2. Belt conveyor ---This conveyor will transport the dried coal briquettes out of the production area for storage.

G. Electric panels

1. Electric panels – The electric panels are to control all the motors and electric parts of the machines in the line, so the line can be controlled easily and conveniently and systematically.

For more details, please send us inquiry directly.