Share with:

For the

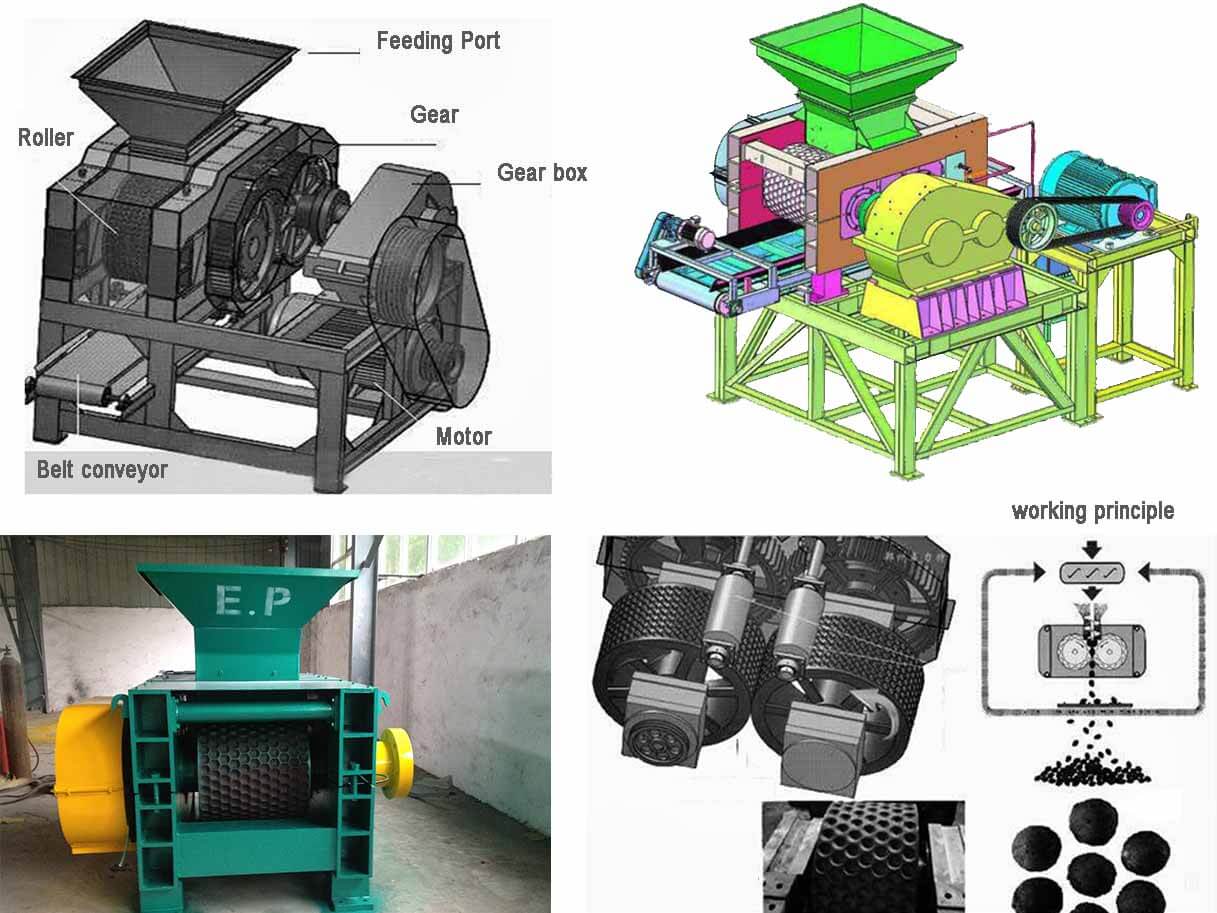

coal briquette machine, how much do you know it? Yes you are right ,the coal briquette machine also named

roller briquette machine,

roller press machine,

briquette making machine. No matter what you call, it has same function to make briquettes.

1.It is a device that presses a powdery material into a ball and mainly used for tailing treatment of minerals, make the powdery materials which difficult to form into ball.

2.It's widely used in coal powder forming, dry powder forming, desulphurization gypsum forming coke powder forming iron filings and various metal mineral powder forming.

Raw material of briquette machine:

1. Charcoal powder, carbon dust, bamboo charcoal dust, shisha charcoal powder, coconut shell charcoal powder, jujube charcoal powder, coke charcoal powder, etc. Besides, our briquette press machine can be also used to press coal, brown coal, white coal powder or dust, coke powder, coking coal, etc. This equipment is widely used in the field of chemical, refrectories, ceramics, mining, and metallurgy, etc.

2. The inlet size of the powdery material should be less than 3mm.

3. We have to add suitable binder of some kinds of material for briquetting.

4. The moisture of material should be moderate, and the water content usually is 12-15%.

Working principle of charcoal dust briquette machine

1. The material is distributed evenly into the molding machine hopper by the storage bin, through adjust the gate on the hopper to make the material into the middle of the roll evenly.

2. The pressure of the unit forming of compressed materials for the roll is changed from weak to strong. In the center line of the roller, the pressure reaches the maximum, and after the material has passed the line, the molding pressure quickly becomes smaller and the material is taken out of the ball and the ball is removed smoothly

3. Final briquette from briquette machine:

1). Shape of briquettes: Our briquette machine can compress the coal powder into square, oval shape, egg shape, round shape, pillow shape, bread shape, cylinder, bar shape, etc. Also you can make the briquettes hollow in the center. Besides, we can according to your special requirements to make the moulds for you, that means you can set the shape by yourself.

2). Size of briquettes: as your needs within a certain degree (10-80 mm).

3). The briquettes produced by our machine are smokless, smelless, because we have the high technology liquid binder recipe.