Share with:

1. INTRODUCTION

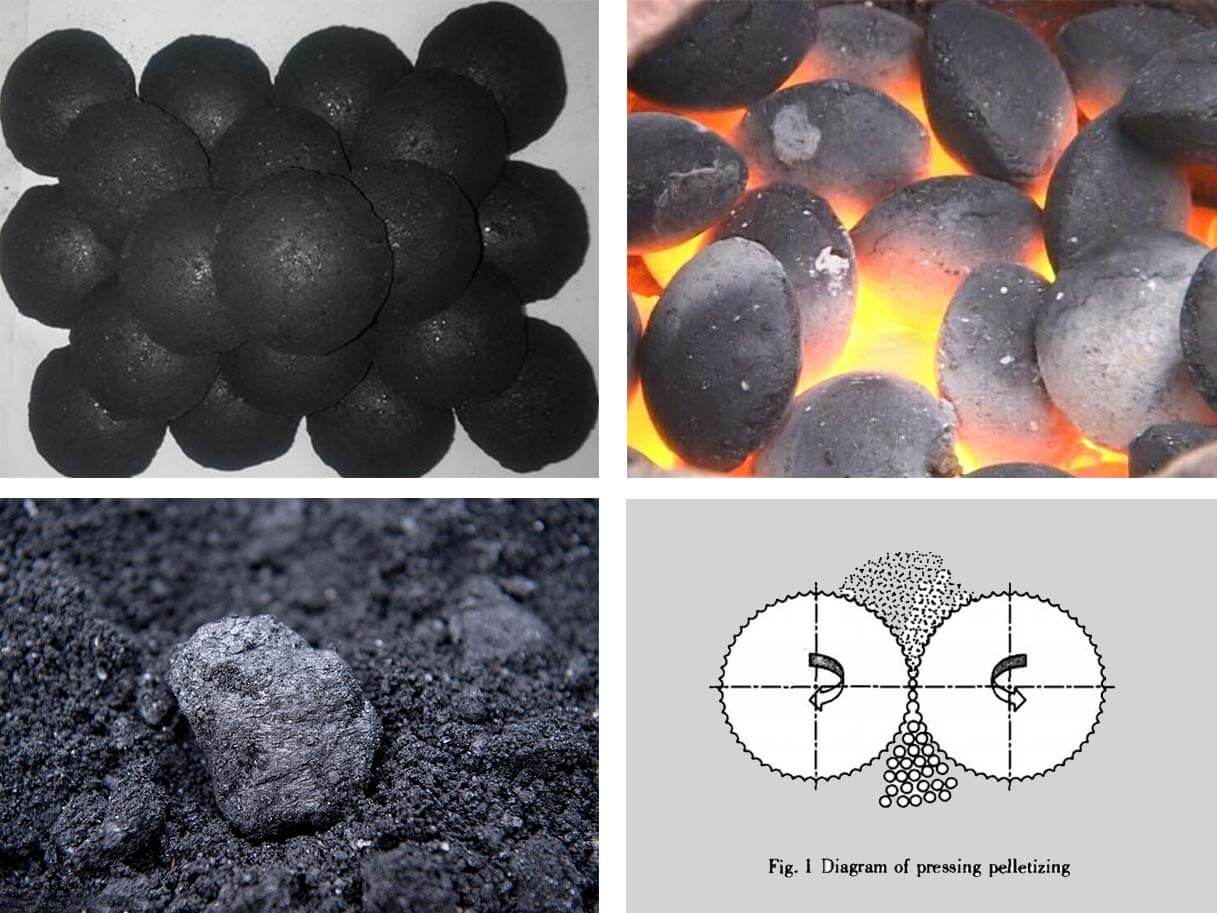

Coal briquettes are made of slack coal powder, washers sink etc. with bentonite, molasses and sodium silicate as bonding materials. These are hard and nut shaped items used as fuel, for burning ovens chullahs in the household kitchens, small restaurants and hotels.

Though there are no specific standards published on coal briquettes, but necessary care should be taken particularly in the process of carbonisation so that the product may not get oxidized or overfeeds. It is also very essential to maintain uniformity in the batch composition, shape and sizes, compactness in the pressing etc. for efficient performance of the product in its end use.

2. MARKET DEMAND

Coal is the cheapest fuel available in the area, the demand of coal and its products always exists in the area. Coal briquette is one of the product, which gives high calorific value with poor class of material too.

These coal briquettes are also substitute for other costly solid fuel like coke briquettes,

charcoal, firewood etc. due to their better ignition properties with less smoke evolution.

Due to poverty in the area, the demand of coal briquettes in the area is tremendous and likely to increase with the increase in population of below poverty line.

As per the last census the below poverty line population in the district is around 2-3 lakhs. If we assume 50% of this population is using the coal briquettes with an average demand of about 1 kg per day per family basis, the total demand of the district would be around 40 -60 MT per day.

Beside above household demand small restaurants, dhabas and hotels also use these coal briquettes and have similar demand to households.