Share with:

The

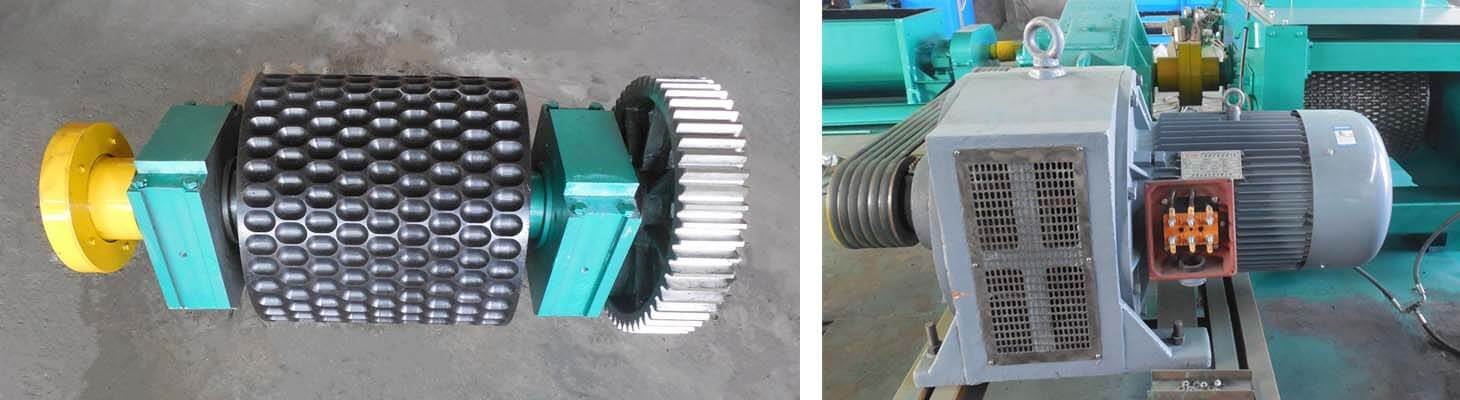

coal briquette machine is used for shaping coal powder into coal briquettes with all kinds of shapes, to make it more efficient for transportation and burning. Commonly, a coal briquette machine consists of 3 main components, including electric motor, gear box and rollers. Here are the details of every parts.

1. Electric motor. The coal briquette machine is driven by a electric motor. Therefore, if you need a stronger machine, the power of electric motor need to be bigger. Besides, as for a high-quality coal briquette machine, the high-quality and famous-brand electric motor is necessary.

2. Gear box. The gear box is used for reducing the speed. We all know that the shaft speed from electric motor is very high, up to thousands rpm. So we need to reduce its speed to a suitable level, to drive the rollers.

3. Rollers. The roller is one of the most important parts of coal briquette machine, especially for the raw materials with high hardness or corrosiveness, the roller will be more easy to wear. Therefore, the roller must be made from high-quality raw materials, such as Manganese alloy, Chromium-Molybdenum alloy, etc. As for a high-quality coal briquette machine, besides the roller is made from high-quality raw materials, it also must be heat treated. After heat treatment, the characteristics of roller will be evidently improved, including its hardness, toughness and abrasive resistance.